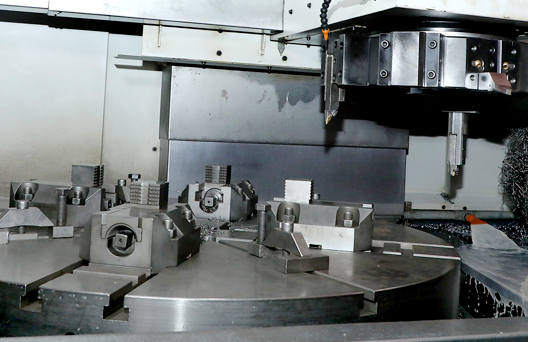

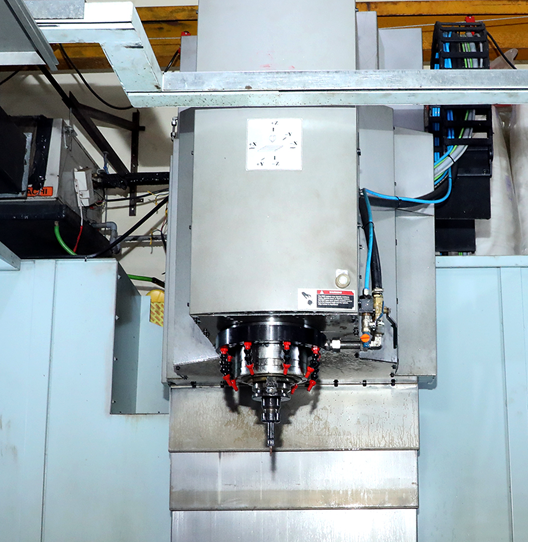

Satyasai uses latest software's and technologies for CAD like unigraphics / solidworks and for CAM we use Delcam / Surfcam for drawing perfect product. On the contrary the products we use are Authorized Version. CNC we use HAAS VM3, BFW BVL 1250 SS & BFW BMV 70 for mold cutting and development.

The advantage of using these machines includes accuracy, productivity, and faster service, maintains quality and reduce manual work for engineering products.

"Manufacturing Flow Process" is one of the reasons that we provide effective customization services to our clients.

Our bulk investments in the infrastructure have ensured that it is equipped with all the requisites facilities.

latest Production workshop

Product Design & Mould Design

Procurement of Steel & Material

Moulding & CNC Programming

CNC Machining

Bench Work & Assembling

Mould Trial First

Inspection & Fine Tuning

Final Mould Trial

Painting Packing &Inspection

Shipping

All these process are fully connected with each other to ensure smooth production of products. Our Production Workshop is well equipped with following machines:

Lathe Machines

Radial drilling Machine

Pentograph Machine

Surface Grinder

Spark erosion Machines- Joemars , Make- Taiwan with orbit cut.

Milling Machine- MMT MITR

Tool Grinder

Bench Grinder

We design Moulds in our in-house design unit which is equipped with the latest CAD/CAM software. Additionally, we possess required facilities and technology to conduct Mould Flow Analysis as required.